The Melt Flow Index Tester is designed to measure the rate of extrusion of a thermoplastic polymer, which provides vital insights into its properties and behavior during processing.

What is the Melt Flow Index Tester?

The Melt Flow Index Tester is an essential device used to determine the melt flow rate (MFR) of thermoplastic materials. The Melt Flow Index Testing is a measure of the ease of flow of the melt of a thermoplastic polymer. This test is critical because it provides a quick and reliable method to assess the flow characteristics of a polymer, which can be indicative of its molecular weight and, subsequently, its processability and performance in various applications.

The tester operates by extruding molten polymer through a die of a specified diameter under a certain load and temperature. The amount of polymer that flows through the die over a specific period is measured and expressed in grams per 10 minutes, which is the Melt Flow Index.

Importance of Melt Flow Index Testing

- Quality Control: For manufacturers, maintaining consistent quality in polymer production is crucial. The Melt Flow Index test helps in monitoring the consistency of the polymer's properties, ensuring that every batch meets the required standards. Variations in MFI can indicate changes in molecular weight, which can affect the mechanical properties of the final product.

- Processability: Understanding the flow behavior of a polymer at different temperatures and pressures is vital for optimizing processing conditions. The MFI test provides valuable data that can help in adjusting processing parameters like temperature, pressure, and time to achieve the desired product quality.

- Material Selection: When selecting materials for specific applications, knowing the MFI can help in choosing the right polymer. Materials with a higher MFI are generally easier to process but may have lower mechanical strength, while those with a lower MFI might be more challenging to process but offer better mechanical properties.

- Compliance with Standards: Many industries and regulatory bodies have specific standards for polymer products, which often include MFI requirements. Regular testing ensures compliance with these standards, avoiding costly recalls or rejections.

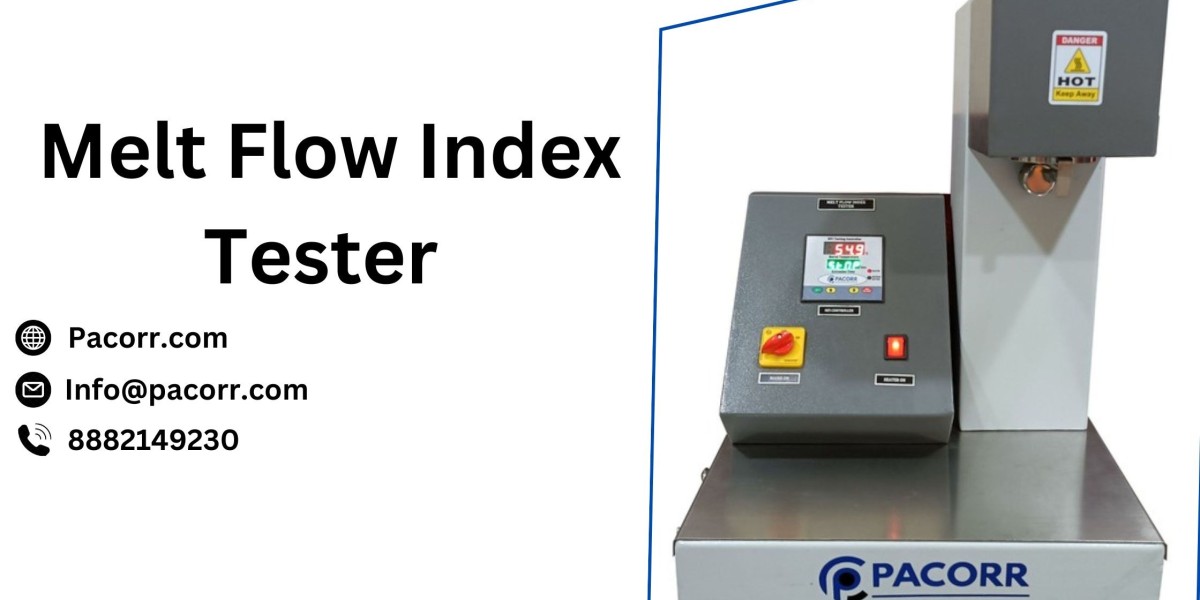

Key Features of the Pacorr Melt Flow Index Tester

Pacorr Testing Instruments Pvt Ltd offers a state-of-the-art Melt Flow Index Tester Price that is designed to meet the diverse needs of polymer manufacturers and researchers. Some of the key features of the Pacorr Melt Flow Index Tester include:

- Precision and Accuracy: The tester is equipped with high-precision sensors and a robust design that ensures accurate and repeatable measurements, even for the most demanding applications.

- User-Friendly Interface: The device features an intuitive interface that makes it easy for operators to set up and run tests, reducing the likelihood of errors and increasing productivity.

- Versatility: The Pacorr MFI Tester can accommodate a wide range of thermoplastic materials, making it suitable for various industries, including automotive, packaging, and consumer goods.

- Compliance with International Standards: The Pacorr Melt Flow Index Tester is designed to comply with global standards such as ASTM D1238 and ISO 1133, ensuring that your products meet the highest quality benchmarks.

- Durability: Built with high-quality materials, the tester is designed to withstand the rigors of industrial environments, providing reliable performance over the long term.

Applications of the Melt Flow Index Tester

The Melt Flow Teste is widely used across several industries, including:

- Automotive: Ensuring the quality and consistency of polymers used in automotive parts is crucial for safety and performance. The MFI test helps in selecting materials that meet the stringent requirements of the automotive industry.

- Packaging: In the packaging industry, the processability of polymers is vital for creating high-quality packaging solutions. The MFI test ensures that the materials used will perform well in various processing conditions, leading to better product outcomes.

- Consumer Goods: For consumer products, where durability and appearance are important, the MFI test helps manufacturers choose materials that will deliver the desired properties.

Conclusion

The Melt Flow Index Tester is an indispensable tool in the field of polymer testing, offering valuable insights into the flow behavior and quality of thermoplastic materials. Pacorr's Melt Flow Index Tester stands out with its precision, versatility, and compliance with international standards, making it an ideal choice for manufacturers and researchers alike.

For more information on the Pacorr Melt Flow Index Tester, visit Pacorr Testing Instruments Pvt Ltd.